Oofos Shoe Scans for Ad Campaign

In a collaborative endeavor with Nice Shoes, MYND Workshop embarked on an ambitious project to digitally immortalize an array of footwear for Oofos using state-of-the-art photogrammetry techniques. This partnership was aimed at crafting high-resolution 3D models that encapsulated every minute detail of the shoes, from the intricate exteriors to the nuanced interiors and the distinctive soles. The process began with meticulous scanning to capture the essence of each shoe, ensuring that the digital twins mirrored their physical counterparts with unparalleled precision.Raw mesh from shoe scanning using photogrammetry (top side)

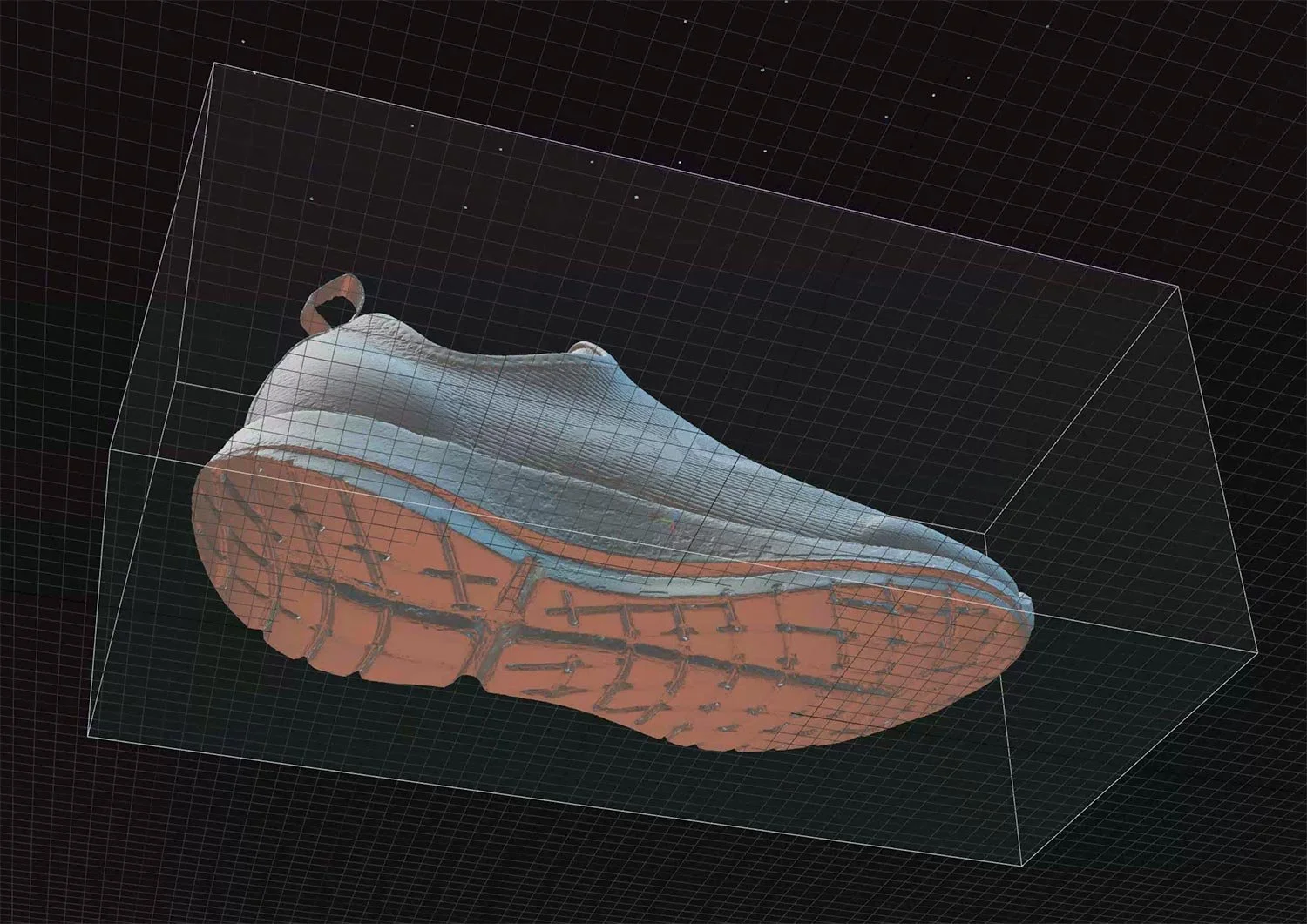

Raw mesh from shoe scanning using photogrammetry (bottom side)

Raw mesh from shoe scanning using photogrammetry

Raw 3D Scan of a shoe using photogrammetry

Raw 3D Scan of a shoe using photogrammetry

Raw 3D Scan of a shoe using photogrammetry

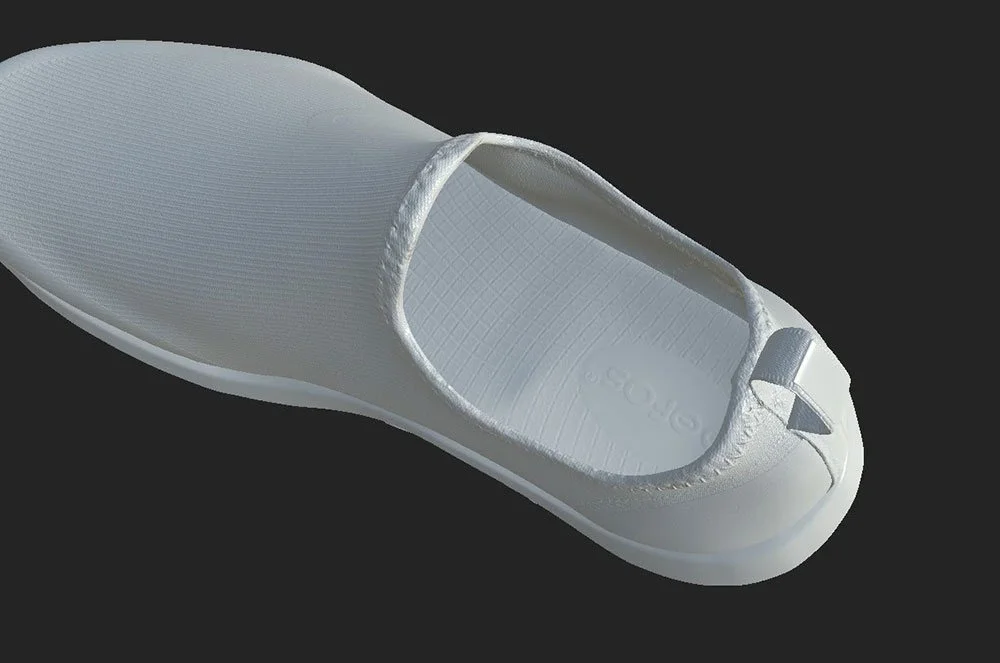

The scanned data then underwent a rigorous process of mesh retopology, where the original complex geometry was refined into optimized 3D meshes. This step was crucial for maintaining the fidelity of the models while ensuring they remained performant for various digital applications. Following retopology, MYND Workshop undertook the intricate task of texture reconstruction. This involved the creation of PBR (Physically Based Rendering) textures, including albedo, normals, metallic, and roughness maps, which were instrumental in rendering the shoes with lifelike textures and materials.Retopologized 3D scan of shoe

Retopologized 3D scan of shoe

Retopologized 3D shoe scan

Retopologized 3D shoe scan

Retopologized 3D shoe scan

Retopologized 3D shoe scan

Custom UV unwrapping and mapping played a pivotal role in this project, allowing for the precise application of textures on the optimized meshes. This ensured that each digital twin not only looked authentic but also interacted realistically with virtual lighting and environments. The culmination of these efforts resulted in a collection of digital doubles that stood as testaments to the synergy between advanced 3D scanning technology and the artistry of digital reconstruction.