3D Scanning for a Fabricated Ray-Ban Ceiling at The Grove L.A.

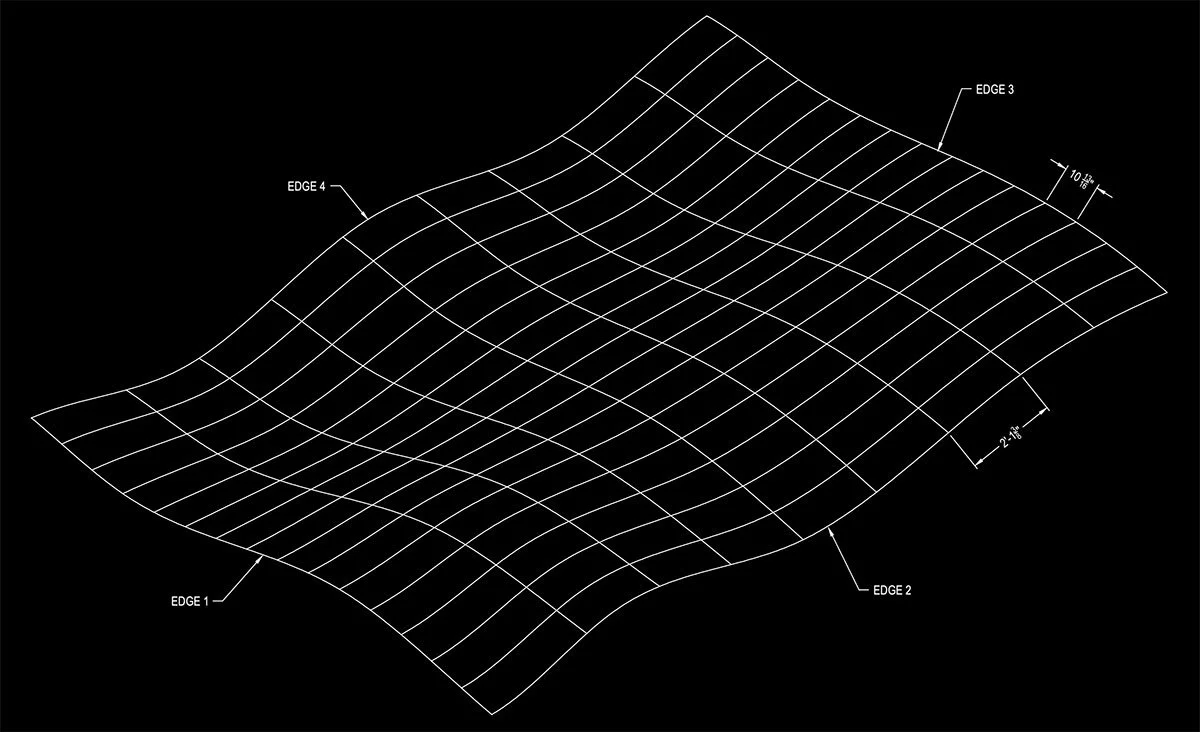

In the fast-evolving AEC (Architecture, Engineering, and Construction) industry, the demand for precision in custom fabrication projects has never been higher. MYND Workshop rose to the challenge at a Ray-Ban store located in the bustling The Grove shopping center in Los Angeles, where a unique design concept called for an as-built ceiling scan of a custom-made ceiling with intricate wave shapes. This project was not just about aesthetics but also about engineering precision, as the ceiling needed to support hundreds of Ray-Ban sunglass lenses, creating an illusion of a wave of lenses floating above the customers. The task required an innovative approach, blending art with the precision of laser scanning to capture the complex shapes of the ceiling.Initial 3D model and plan for 3D prints (before as built laser scan)

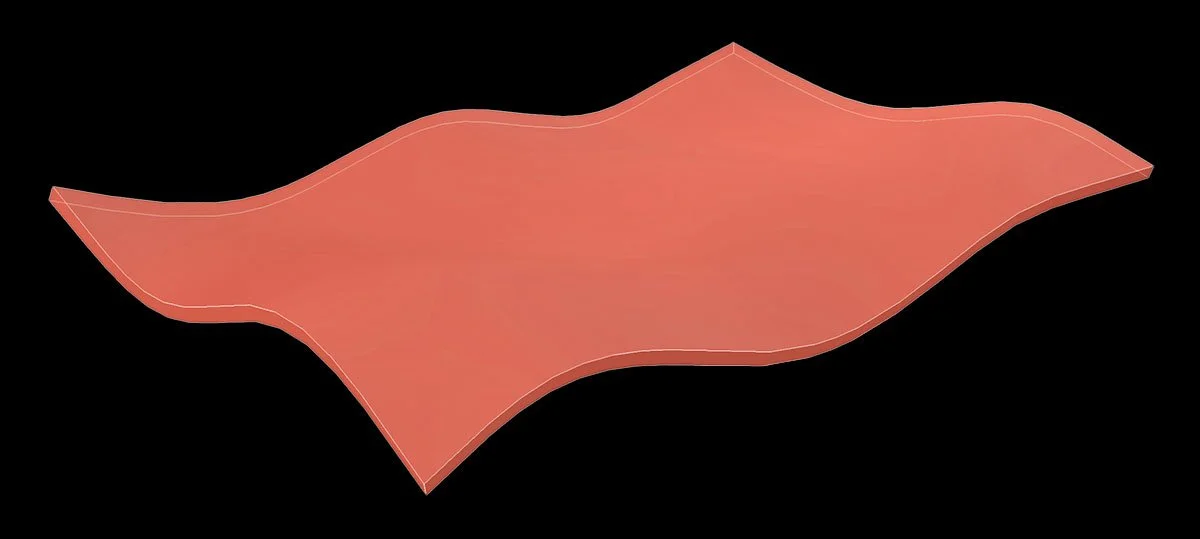

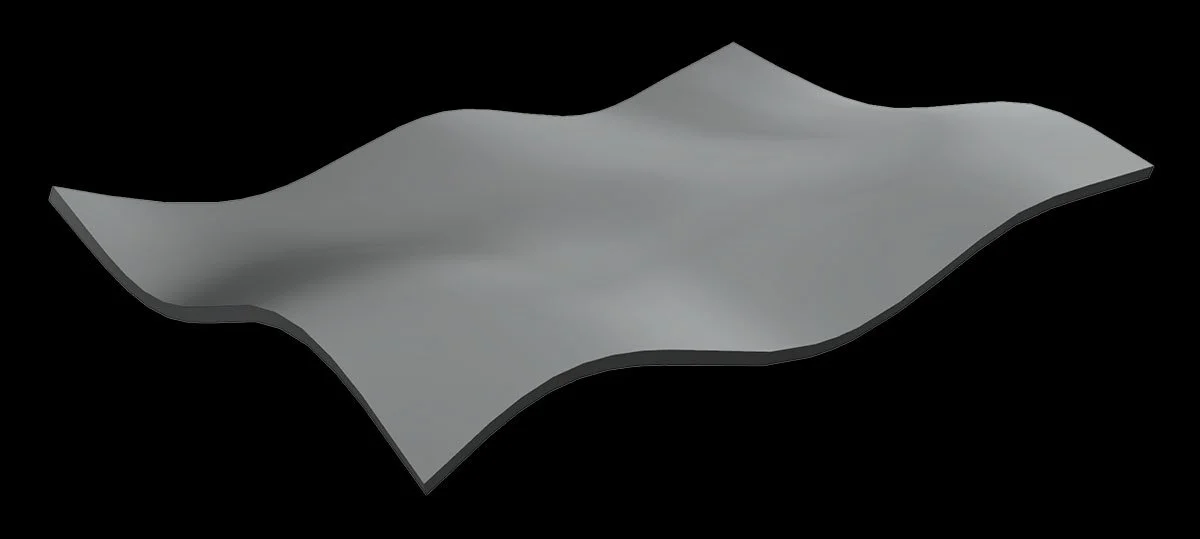

3D model provided to fabricator for 3D printing (after as built laser scan)

Initial 3D model and plan for 3D printing (after as built laser scan)

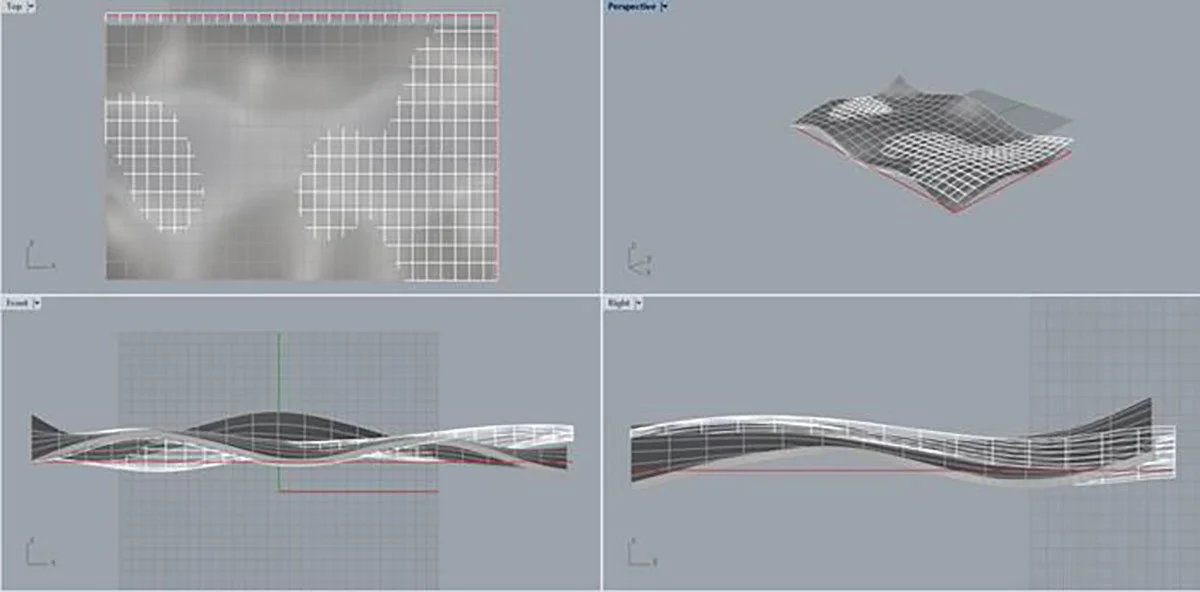

Comparison showing difference between original model and as-built laser scan

Laser scanning stood out as the only viable method to ensure that the 3D printed attachments would align flawlessly with the ceiling's undulating contours. Utilizing advanced laser scanning technology, MYND Workshop was able to produce millimeter-accurate scans of the ceiling, capturing every nuance of its complex wave shapes. This level of detail was crucial for the custom fabrication process, ensuring that each piece would not only fit perfectly but also contribute to the overall visual impact. The high-resolution 3D model generated from these scans provided the contractor with the precise files needed to fabricate the 3D printed pieces, bridging the gap between digital design and physical reality.Contractors installing the 3D printed panels onto the ceiling

The final wave-shaped ceiling with Ray-Ban sunglass lenses

The final wave-shaped ceiling with Ray-Ban sunglass lenses

The completion of the Ray-Ban store project at The Grove stands as a testament to the synergy between cutting-edge technology and creative vision in the AEC industry. MYND Workshop's expertise in as-built ceiling scans and laser scanning for custom fabrication allowed for the seamless integration of complex shapes into a functional and visually stunning design. This project highlights the transformative potential of laser scanning in bringing complex architectural concepts to life, ensuring accuracy and aesthetic appeal in equal measure. The floating wave of sunglass lenses above the customers not only enhances the shopping experience but also serves as a benchmark for innovation in retail space design.